Introduction to Whey Protein Powder

Whey protein powder has become a go-to supplement for fitness enthusiasts and athletes. This nutrient-dense powerhouse is favored for its high-quality protein content, which aids in muscle recovery and growth. Extracted from milk during cheese production, whey protein provides a complete amino acid profile, making it an exceptional addition to any diet.

Understanding how whey protein powder is made enlightens consumers about the product’s journey from farm to shaker bottle. The process begins with the collection of cow’s milk, proceeds through various stages including pasteurization and filtration, and ends with the packaging of a fine, nutrient-rich powder.

This guide will walk you through each step in detail, ensuring you grasp the comprehensive method behind whey protein powder creation. Let’s embark on this fascinating process that transforms simple milk into a fitness supplement staple.

Origin of Whey: From Cattle to Dairy

Whey protein powder has an agricultural start. It comes from cows, mainly raised on dairy farms. The process starts with the careful selection of these cattle. Healthy cows produce the high-quality milk needed for whey production.

Sourcing Milk for Whey Protein Production

Milk sourcing is a critical step in making whey protein powder. Dairy farmers ensure their cows have a nutritious diet. This leads to milk rich in proteins and suitable for whey extraction. They then collect the milk under strict hygienic conditions. This is to keep it free from contaminants. Then, it’s ready for the next step, pasteurization. High standards during milk collection ensure the final whey product is of superior quality.

The Science of Pasteurization

Pasteurization is essential in whey protein production. This process heats milk to eliminate harmful bacteria. It prevents foodborne illnesses and extends milk’s shelf life. This step is crucial for safe consumption.

Understanding Milk Treatment Methods

To understand pasteurization, think of it as a safeguard. The milk heats to about 73 degrees Celsius, then cools quickly. This process retains important nutrients but kills bacteria. It’s a balance ensuring milk safety and nutritional value.

Cheese Making: The Byproduct of Whey

The production of whey protein powder is closely linked to cheese making. During this process, milk is curated and separated into solid curds and liquid whey. This division is vital, as the liquid whey is what will eventually become the protein powder many rely on for their nutritional needs.

Separating Curds and Whey

To separate the curds from the whey, specific enzymes, such as rennet, are added to the pasteurized milk. This causes the milk to curdle and solidify into curds. These curds are later used to make various types of cheese. Meanwhile, the leftover liquid, which is full of protein, lactose, and minerals, is collected. This liquid whey is then processed further to create whey protein powders. As part of ensuring the quality of the end product, dairy farms employ stringent hygienic practices from the very start of the milk collection process. This cleanliness is essential for producing high-quality whey protein that is both nutritious and safe for consumption.

Filtering Process: Achieving Whey Concentration

After the initial cheese-making steps, the leftover liquid whey contains not only protein but also fats, carbohydrates, and minerals. To increase the whey protein content and remove other components, filtering is an essential process. This stage involves passing the liquid whey through a series of fine filters. This separates the protein from the fats and lactose, resulting in a more concentrated protein solution known as Whey Protein Concentrate (WPC).

Proper filtration is crucial for the quality and efficacy of the final whey protein product that consumers rely on for their dietary needs.

The Journey from Liquid to Powder

Transitioning from liquid whey to whey protein powder involves further processing steps. The concentrated whey solution must undergo a careful drying process. Here, it is exposed to both hot and cold air in a spray drying apparatus. This effectively removes moisture without damaging the proteins.

Spray drying involves rapidly evaporating the water from the whey solution, causing the proteins to solidify. Once the desired consistency is reached, what remains is a fine, dry powder. This whey protein powder is almost ready to be packaged, but first, it goes through a series of quality checks and tests.

The powder-form of whey protein is much easier to handle, transport, and incorporate into various products. This is why the drying process is a key transformational step in whey protein manufacturing. By converting whey protein into a powder, it becomes convenient for consumers to measure, blend, and consume as part of their daily nutrition routine.

The Role of Enzymes in Whey Extraction

In the making of whey protein powder, enzymes play a pivotal role. They kickstart the separation of whey from milk during cheese production. This is when milk undergoes coagulation, splitting into solids (curds) and liquids (whey). Enzymes, such as chymosin, are added to pasteurized milk to facilitate this division. It’s a critical step for deriving the nutrient-rich whey needed for protein powders.

Casein Removal and Whey Isolation

The process targets the extraction of whey, leaving behind casein. Casein is a protein that coagulates to form cheese. Its removal is essential, as the focus is on capturing the liquid whey containing valuable proteins. During this phase, the application of enzymes causes milk to curdle. Consequently, casein solidifies and separates from the liquid whey. The liquid is then collected for further refinement into high-quality whey protein powder. This separation process ensures the protein in whey remains intact and highly beneficial.

Ultra-filtration: Crafting Whey Protein Isolate

To craft Whey Protein Isolate (WPI), ultra-filtration is key. In this step, the protein reach above 90% purity. This happens as whey concentrate goes through tiny filters. These filters catch large elements like fats and lactose. Small molecules, mostly protein, pass through. This step cuts down carbs and fats, leaving behind high-quality protein.

Refining the Protein Content

To refine protein, more filtering rounds occur. Each round boosts the protein purity. Checks are in place to keep proteins intact. This gives a product rich in protein with less fats and carbs. A fine balance ensures all amino acids stay complete. WPI usually holds 90% or higher protein content due to these steps. This makes it a top pick for muscle building and recovery.

Drying and Powder Creation

After ultra-filtration, the journey of turning liquid whey into a fine powder begins. This stage is called spray drying, and it’s as advanced as it sounds. Huge machines spray the filtered whey through hot and cold air. This removes water quickly and leaves behind a dry powder. This powder is now pure whey protein, ready for the next steps in production.

Keeping the quality high during spray drying is crucial. The air temperature needs careful control. Too hot, and the protein might change, losing its powerful benefits.

Final Touches Before Packaging

Before whey protein powder can be packed, there are a few ‘final touches’. First, it’s tested for consistency. The powder must be fine, with no lumps, for easy mixing in shakes. Then, it’s tested for flavor. While some prefer it unflavored, others like a bit of taste.

The next step is crucial – it’s safety testing. This is where the powder is checked for harmful bacteria or metals. Only when it passes all these checks does it move to packaging. The aim is to ensure that every scoop you take is safe and beneficial to your health. Quality control is non-negotiable in whey protein production.

Quality Control and Testing

Ensuring Purity and Potency

Each batch of whey protein powder must pass purity tests. Tests detect any harmful substances like heavy metals or bacteria. Potency checks are also critical. They confirm the protein content matches what’s on the label. High-quality whey should have all the amino acids listed, which are essential for muscle building and repair. Only when these tests are passed, can the whey protein powder proceed to packaging and distribution.

Packaging, Flavoring, and Shipping

After ensuring whey protein powder’s quality and purity, we move to the final stages. First comes packaging. This process involves measuring the correct amount of powder and sealing it in containers. It’s done under strict, hygienic conditions to prevent contamination.

Next, we talk about flavoring. While some people prefer plain whey, others enjoy flavors. We add natural flavors like chocolate or vanilla. This makes the powder tastier for those who want it. Care is taken to use flavors that do not compromise the protein’s benefits.

Lastly, shipping is where the final product leaves the facility. It’s sent out to stores or directly to customers. Careful handling ensures the product arrives fresh and intact. Safe delivery is our goal, so you can enjoy your protein with confidence.

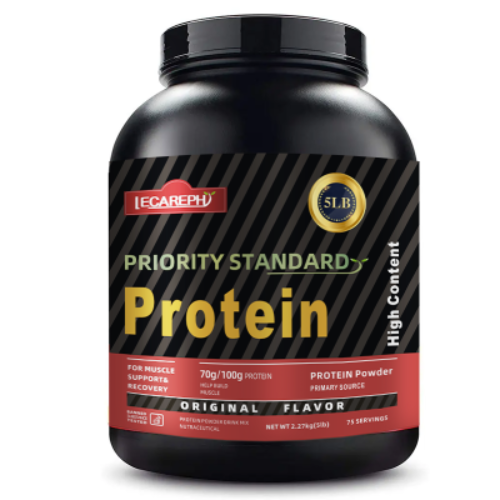

The Final Product Ready for Consumers

The journey from farm to shaker bottle concludes here. The whey protein powder, now packed and flavored, reaches you, the consumer. It’s ready for you to consume and support your fitness goals. Every scoop offers high-quality protein to aid in muscle growth and recovery.

What’s on the label matches what’s inside. We ensure this through rigorous quality control. This is our commitment to providing a pure and potent product. Now, enjoy your protein shake knowing the care that went into making it.