How do they make protein powder? From Source to Supplement

Protein powder has become a staple in the fitness industry and for many health-conscious individuals. This convenient supplement offers an easy way to increase protein intake. However, few people know the extensive process involved in producing it. Understanding this process can help consumers make informed choices about the products they purchase.

Sourcing Quality Protein

The first step in making protein powder is sourcing the raw ingredients. Protein powders can be derived from various sources, including dairy, plants, and eggs. Each source has unique characteristics, benefits, and nutritional profiles. Whey protein, for example, is derived from milk and is popular for its quick absorption rates. In contrast, plant-based proteins come from sources like peas, brown rice, or hemp and cater to a growing vegan market.

Dairy-Based Proteins

Dairy-based proteins, particularly whey and casein, are prevalent in the supplement industry. Whey protein is a byproduct of cheese production. This byproduct undergoes several filtration processes to refine it. During this process, excess fats and carbohydrates are removed, leaving behind concentrated protein.

Casein, another dairy protein, is digested more slowly. This slow absorption can provide a more prolonged release of amino acids. Producers often emphasize the importance of high-quality dairy sources. They source milk from farms with good animal welfare practices, ensuring that their protein is clean and nutritious.

Plant-Based Proteins

On the other hand, the demand for plant-based proteins has skyrocketed in recent years. As more people adopt vegetarian or vegan lifestyles, companies are responding to this trend. Sourcing high-quality plant proteins involves harvesting legumes, grains, and seeds. These proteins are extracted through mechanical or chemical means, depending on the source.

Pea protein, for example, is derived from yellow split peas. It’s considered an excellent option for muscle recovery. Companies usually emphasize non-GMO sources, attracting health-conscious consumers. Ingredients like brown rice or quinoa provide a complete amino acid profile when combined with pea protein. This approach appeals to those looking to meet their protein needs without animal products.

Extraction Processes

Once the raw materials are sourced, the next step is protein extraction. Various methods exist for this process, each with its advantages. Companies aim to optimize extraction methods to retain as many nutrients as possible while maximizing yield. This step is critical for ensuring the final product meets consumer expectations regarding taste and effectiveness.

Mechanical Extraction

Mechanical extraction is often used for plant-based proteins. This method typically involves grinding, pressing, and filtering the raw material. The goal is to separate the protein from other components like fats and carbohydrates. For instance, pea protein is finely ground to produce a protein-rich extract.

This process retains most of the key nutrients found in the source material. Customers seeking natural supplements usually prefer mechanical extraction methods. They often appreciate that this method uses fewer chemical agents. Additionally, mechanical extraction tends to be more environmentally friendly.

Chemical Extraction

In contrast, chemical extraction involves using solvents to separate proteins from their source. This method can increase yield but may compromise some nutritional value. For instance, soy protein isolate is often made using chemical solvents. While this produces a highly concentrated protein product, it may strip certain nutrients during the process.

Companies often provide information on their extraction methods for transparency. Consumers can then make informed choices based on their preferences. Those who prioritize nutrient retention may prefer products made with mechanical extraction. It’s essential to research the methods behind the brands being considered. This effort ensures the best choice aligns with individual dietary goals and values.

Formulation and Flavoring

Once extraction is complete, the next step is formulation. This is where companies create the final product. They decide on the protein concentration, texture, and flavor. For many brands, this phase is crucial to ensuring the product meets market demands and consumer preferences.

Blending Proteins

Some products use a blend of different proteins to enhance their nutritional profile. For example, combining whey and casein offers both fast and slow-digesting proteins. This blend can appeal to those needing quick recovery and sustained energy release. Similarly, combining various plant proteins maximizes the amino acid spectrum.

The art of formulation involves balancing taste, texture, and solubility. Companies conduct extensive taste tests to find a flavoring that appeals to consumers. Popular flavors include chocolate, vanilla, and strawberry. Improving the product’s mouthfeel can influence consumer satisfaction significantly.

Adding Other Ingredients

In addition to protein, many products contain additional ingredients. These can include vitamins, minerals, or digestive enzymes. For example, some brands add probiotics, enhancing gut health. Consumers looking for a comprehensive supplement may appreciate these additions.

Companies also pay attention to the sweeteners they use. Natural sweeteners like stevia and monk fruit are popular alternatives to artificial sweeteners. Consumers increasingly prefer cleaner labels, and this trend influences formulation choices. Businesses that embrace this approach often see higher customer satisfaction and loyalty.

Quality Control and Testing

Quality control is a crucial aspect of the protein powder manufacturing process. Companies undergo rigorous testing at multiple stages to ensure product safety and efficacy. This process involves several checks, from ingredient quality to finished product testing.

Raw Material Testing

Before processing begins, raw ingredients undergo thorough testing. This step often includes checking for contaminants such as heavy metals and microbes. Suppliers must meet strict quality standards to ensure that their ingredients are safe and nutrient-dense.

Companies may use third-party labs to validate their findings. This independent verification can enhance consumer trust. More customers seek transparency, and third-party testing provides an extra layer of assurance. Brands that invest in quality measures often attract a dedicated customer base.

Finished Product Testing

After formulation, the final product is subjected to rigorous testing as well. This step evaluates potency, flavor, and texture. By assessing these factors, manufacturers ensure the product meets their quality standards. Additionally, shelf-life studies help determine how long the product can be stored without degrading.

Consistency is key when it comes to quality control. Brands strive for uniformity in taste and nutritional content across all batches. This consistency fosters customer loyalty and satisfaction. In an industry marked by fierce competition, quality can be a substantial differentiator.

Packaging and Marketing

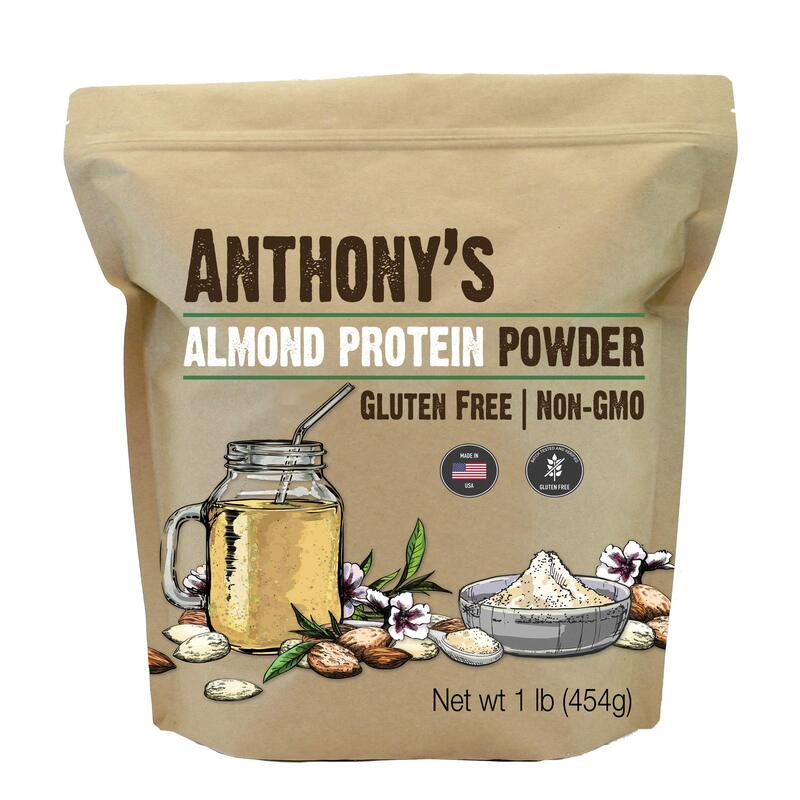

After passing quality checks, the product is ready for packaging. Packaging is a vital phase in the protein powder production journey. It impacts shelf life, branding, and consumer perception. Sustainable packaging options have gained popularity, emphasizing a commitment to the environment.

Innovative Packaging Solutions

Packaging options range from resealable bags to containers made from recycled materials. Brands increasingly utilize eco-friendly packaging to appeal to environmentally conscious consumers. Innovative packaging solutions can also enhance convenience and usability. Easy-to-use scoops or measuring guides can improve the user experience.

Furthermore, packaging design plays a significant role in marketing. Eye-catching designs and informative labeling often draw potential buyers’ attention. Clear nutritional information and effective branding help convey the product’s benefits. Companies that invest in attractive, informative packaging often achieve better sales.

Strategic Marketing and Branding

Once the product is packaged, marketing strategies come into play. Companies target specific demographics, such as athletes, fitness enthusiasts, or health-conscious consumers. Digital marketing strategies, including social media and influencer partnerships, have surged in popularity.

Effective messaging can highlight the product’s unique selling points, such as organic sourcing or superior taste. Word-of-mouth marketing is still a powerful tool, particularly in the fitness community. Companies often sponsor athletes or fitness events to gain credibility and visibility. In a crowded market, a solid marketing strategy is crucial for success.

Sustainable Practices in Production

With growing awareness of environmental issues, many protein powder companies are adopting sustainable practices. Sustainability is not just a trend; it’s becoming a necessity in the supplement industry. As consumers demand more eco-friendly products, companies are adjusting their operations accordingly.

Sourcing Sustainably

Many brands are sourcing ingredients from farms that follow sustainable practices. These farms often prioritize organic methods, minimizing chemical use, and promoting biodiversity. Sourcing sustainably can also include working with local suppliers to reduce transportation emissions.

Additionally, some companies emphasize the ethical treatment of animals, especially in dairy-based protein production. Transparency about sourcing helps build trust with consumers. Brands that prioritize ethical and sustainable practices often stand out in a competitive marketplace.

Eco-Friendly Manufacturing

Moreover, companies are also focusing on sustainable manufacturing processes. This involves reducing water usage and energy consumption during production. Implementing eco-friendly technologies can help achieve these goals. Many companies are investing in renewable energy sources, such as solar or wind power.

Recycling and waste management practices are also critical. Brands that minimize waste during production often have a smaller environmental footprint. By adopting these practices, companies not only cater to eco-conscious consumers but also contribute to global sustainability efforts.

The Future of Protein Powder

As the protein powder industry evolves, new trends are emerging. Continuous innovation is essential in meeting changing consumer needs. Companies are consistently looking for ways to enhance their product offerings and stay ahead of the competition.

Advanced Protein Sources

The future may bring new protein sources into the mix, such as insect proteins or lab-grown options. These alternatives may offer higher sustainability and nutritional benefits. Consumer acceptance will be crucial for the success of these emerging sources. As awareness grows regarding traditional livestock farming’s environmental impact, acceptance may increase.

Another avenue for innovation is personalized nutrition. Advances in technology may allow consumers to tailor protein powders to their specific needs. This customization can improve health benefits and consumer loyalty. Brands that embrace personalization can differentiate themselves in a crowded market.

Enhanced Nutritional Formulations

The demand for functional foods is also rising. More consumers want protein powders that offer additional health benefits. This may include enhanced formulations with superfoods, adaptogens, or additional vitamins. Companies continually experiment with unique ingredient combinations to meet this demand.

Moreover, as research evolves, new findings may influence the formulation processes. Nutritional science is an ever-changing field, and staying up-to-date is crucial. Brands that adapt to new research can better cater to their customers’ evolving needs.

Conclusion

The journey of protein powder from sourcing to supplement is complex and multi-faceted. From choosing quality ingredients to innovative packaging and marketing, each step is critical. As the industry continues to evolve, companies must adapt to changing consumer demands and sustainability challenges. Understanding the intricacies behind protein powder production empowers consumers to make informed choices. As consumers become more educated, they can seek brands that prioritize quality, sustainability, and transparency. By investing in products that align with their values, consumers can support a healthier lifestyle and a more sustainable future.